Contact Us

Name:Mr Yang

Tel: +86.0539-8652762

Fax: +86.0539-8652763

E-mail: mengshandiantan@163.com

Website: http://www.lymsdt.com

Address: Baisha Town, Linyi City, Shandong Province, Zhu Pan Industrial Zone

Knowledge

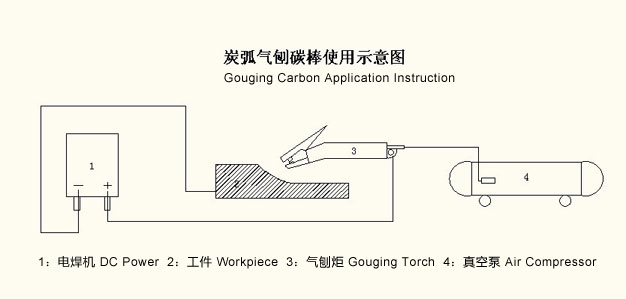

Technology perfrmance:air-arc carbon rod gouging technology is mainly applied in the fields of metal structure,metal casting,and shipbuilding,etc,it enhances processing efficiency,and improves working condition by adopting the technique of airarc carbon gouging instead of the old pneumatic chiseling.The metal surface treated by carbon rod gouging is smooth clean and flat without ant harmful infiuence to the metal Performance.It is featured by convenient operation,low cost and noiselessness.

技术性能:弧气刨工艺主要应用与金属结构、金属铸造、造船等行业。采用碳弧气刨工艺代替旧式风铲,具有加工效率高,改善工作条件,加工的金属表面光洁平整,对被加工金属的性能不产生有害影响,才做方便、经济节约、无噪音等优点。

Attention to the usage of air-arc gouging cai-bon electrode:

1、Power:Normal D.C.for welding machines can be used for air-arc gouging car-bon electrode.

2、Range of currency:The currency range adopted directly influences the processing quality and results.if it is too small.it will be dif ficult for gouging;if too large ,it will cause heated carbon head too long,which will result in the rod becomes thinner and the processing qualitypoor.Therefore the proper currency range as shown in the table herewith should be adopted in accordance with the model and dimension of gouging carbo electrode.

3、Range of Air pressure:The normal air pressure range is 4-6kg/cm2,which shall be in compliance with the diameter of gouging carbom electrode.in general,higher air pres-cure is for bigger diameter of the rod and lower pressure for smaller diameter. if air pressure for smaller diameter.if air pressure is too high, electrical arc is unstable;if too low, melted metal can not be blew off easlily, which will infulecce the quality of gouging groove

碳弧气刨碳棒注意事项:

1、电源:一般的直流电焊机所用电流即可作为碳弧气刨碳棒的直流电源。

2、电流范围:使用的电流范围是否适宜,直接影响加工的质量与效果,选用的电流范围过小则刨槽困难,电流范围过大则碳棒头部的烧红部分过长十碳棒头部变细,刨槽宽窄不一影响加工质量,应该按照碳棒型号、规格选用表上所表示的电流范围。

3、风压范围:一般选用的风压范围是4-6kg/cm2风压的大小与碳棒直径的大小有关。直径大的碳棒选用较大的风压。直径小的碳棒选用较小的风压,如果风压过大则电弧不稳定。风压过小则熔化的金属熔渣不易吹开,影响刨槽质量。